Harmonic Filter Solution

Harmonic Filter solution is an engineer's approach to increasing 3P, Power, Productivity and Profitability. No stoppage. No breakdown. No quality rejection. Or for that matter, harmonic filtering reduces end-product quality rejection and in-process scrap generation by over 50% on a six-sigma scale for the manufacturing process industries. Power quality stoppages, plant breakdowns and equipment failures get mitigated by over 90%.

Cost Saving on end-product quality rejection and in-process scrap generation: There is a good reason as to why the harmonic filter solution achieves over 50% reduction in end-check product quality rejection and in-process scrap generation on a six-sigma scaling.

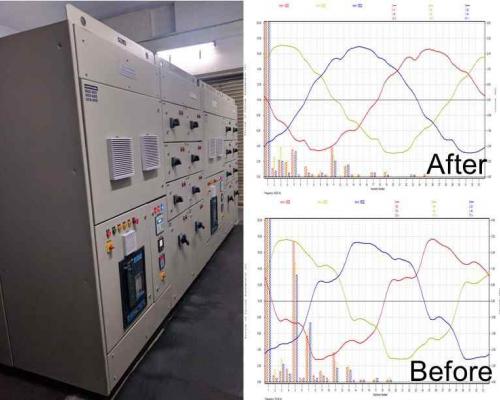

Energy Saving: Passive Tuned Harmonic Filter reduces a factory's net energy cost between 3% to 8% in most distortion correction projects with nonlinear loads. The energy saving in kWh term is verified by comparing the plant's energy consumption data one year before and one year after the implementation of the harmonic filter solution. Harmonic filter improves both the load power factor and the distortion PF and maintains the facility's average power factor at UNITY LEVEL consistently with variable process loads.

Equipment Failure Reduction: The most major advantage of the harmonic filter solution is that it eliminates over 80 to 90% failures and nuisance tripping problems in the facility with the electronic card, HMI/ SCADA/ Industrial Computer/ Server, variable speed (frequency) drive, dc drives, motors, and other electrical equipment.

Increases Solar Power Generation: Manufacturing industries are increasing installing photovoltaic solar power generation plants ever since solar power costing has become competitive with respect to coal-based thermal power plant's cost. There is a good reason as to why the harmonic filter achieves Extra Solar Power Generation and in-addition eliminates solar inverter's nuisance tripping problem. For a solar inverter case study please visit the web-page solar power inverter with harmonic filter.

Fully Automatic Operation with highly variable process loads: The variable harmonic filter runs without any manual interruption that including switching off while on a holiday and switching on again, once the loads restart. It allows automatic changeover between the utility power and the backup diesel generator source on a power outage and vice versa once the utility supply resume. It allows automatic reactive power control for power factor management with highly variable loads. It controls harmonics, both voltage and current harmonics, with highly variable process loads within the regulatory norm of the IEEE-519 standard.

Harmonic Filter Solution is for the Life Long: The designed Life of a high quality Tuned Passive Harmonic Filter is over 40-Years and it practically needs no-maintenance except for routine maintenance needs like occasional cleaning and tightening.