Harmonic Analysis | Encon Engineers

How NLL affect today's electrical power system? A study of electrical power harmonic analysis helps to know the root cause of equipment and drive failure for correctional power-related steps. Today's Engineers are finding a power quality problem that is becoming increasingly apparent is the harmonic distortions of the fundamental waveform. The problem has arisen due to extensive use of Non-Linear Loads (NLL) in today's electrical power system, which alter sinusoidal shape of the sine wave, and thereby cause harmonic generations and distortion power factor (PF) in the power System.

Harmonics are as old a phenomenon as the introduction of the AC System. Mercury Arc Rectifier (MAR) developed in 1920's and Semiconductor Controlled Rectifiers (SCR) and Thyristors developed in 1950's created harmonics due to their nature of non-linear-load. Its usage was much lesser then, typically 5% in 1960, that could not have created any significant impact on the power system. However, economic prosperity coupled with technological advancements have mandated today's comfort conditions those necessitate employing matching controls which are increasingly introducing nonlinear loads which are altering the very sinusoidal characteristic of current and voltage waveforms and creating Harmonics and bad Power Quality.

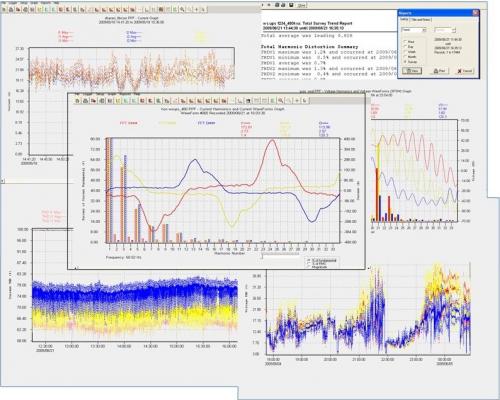

Measurement units of Power Quality Harmonics are defined by Total Voltage Harmonic Distortion THDv and Total Current Harmonic Distortion THDi. THD values are calculated as the sum of square root of individual harmonics namely 2nd, 3rd, 4th, 5th, 6th, 7th, ... nth divided by fundamental current/voltage. The fundamental harmonics are the 50hz/ 60hz values for voltage and current.

The Conventional engineering design: It lowers the plant's Load Factor wherein the degree of equipment derating scales up with the degree of Nonlinear loads. It helps in skirting the problem but with a guzzling infrastructure that not only produces lesser quality of products but also requires higher investment cost for having higher sized equipment. The plant's power system though manages to survive the harmonics onslaught, the virus remains in a dormant stage that occasionally could strike under its favorable power quality conditions. The least it creates energy losses and occasional equipment tripping. Electronics are first to fail as being the most susceptible followed by capacitors, fuses, switchgears, motors -ac/dc/servo, ct, pt, transformers, cables and its terminations.

The most common Harmonic Problem that we encounter while conducting field measurement and harmonics analysis is capacitor and detuned filter drawing high current, bulging, flashing and even blasting of capacitors, reactors or switchgear. Capacitors themselves do not cause any harmonic problem. But if significant Nonlinear loads are present in the electrical power system it aggravates a potential harmonic problem. Any combination of capacitance and inductance forms a Resonance Frequency at which the capacitive and inductive reactance equals. If significant harmonic energy is present either inside the plant or outside in the Grid and its frequency matches with the resonance frequency formed by the Power Factor (PF) correcting capacitors or Detune Filters, it excites current into an oscillation, and results in high harmonic magnifications. Its effect can damage equipment and reflect in an excessively high harmonic distortion, both in voltage and current. Our harmonic audit across most industry segments find following types of equipment failures due to harmonic distortions and bad power quality failures.

Electronics: Electronic failure issues happen with ac vfd drives, DC drives, power electronics- IGBT/ Thyristors/ SCR/ Diodes, PLC, DCS, SCADA, Industrial PC, HMI, UPS cards, spike and surge arrestors, Thyristor Fuse, Computer/ Lab/ Data Center/ Server- hard disk drives, CPU-motherboard, Controller-cards, SMPS-power supply boards, and communication equipment. Encon Tuned Harmonic Filters suppress both voltage and current harmonics from power system and provides a clean and quality power solving electronic failure issues.

Squirrel Cage AC Induction Motors: In SQIM motors the initial harmonic problem shows up with high bearing temperature and unbalance three phase current. It eventually leads to stator winding failure-burn/ground fault/phase-to-phase short circuit or winding coil melt open. Motor switch-on failures mostly occur with stator windings, but occasionally even the sturdy rotor bar damage due to high inertia load and magnetic core saturation during the high starting current period. Passive tuned harmonic filter mitigates harmonic distortions from motor's incoming power supply eliminating failures.

Slip Ring AC Motors: In SRIM motors the initial harmonic problem shows up with high bearing temperature and unbalance three phase current. It eventually leads to stator winding failure-burn/ground fault/phase-to-phase short circuit or winding coil melt open. Harmonic failures happen with rotor's external copper link, ring and air cooled resistance, which burn from prolonged harmonic overheating. Even the sturdy rotor windings fail. Motors. Motor switch-on failures occur through rarely, but do happed stator windings, due to high inertia load and magnetic core saturation during the high starting current period. At HT motors, specific power quality and harmonic failures include insulation failure or terminal connection melting between rotor coil and its slip ring, rotor shaft and/or its gear box (GB) damage or break down. Those happen if excessively high harmonics are present in factory's electrical power system or due to an occurrence of series harmonics resonance by interaction between the power systems of the utility/grid and the plant with presence of harmonics. Passive tuned harmonic filters block grid/utility related harmonic resonance situations and thus prevent the possibility of extreme harmonic distortions entering into plant's electrical power system through series resonance, and eliminates failures with large HT motors. Further ac motor failures happen due to high harmonic distortions in the power system because of use of nonlinear loads. Passive tuned harmonic filter mitigates harmonic distortions from motor's incoming power supply eliminating failures.

DC Motors: In DCM, the initial harmonic problem shows up as field overcurrent, commutator overheating, and soon it leads to irregular gap between commutator segments which happens when soldering bond between them gives up. Harmonics cause field winding failures- burning /grounding/ melting/ or the winding coil opening. Even the study armature windings fail- burning/ earthing/ melting/ or the winding coil opening and occasionally even the sturdy commutator fails due to overheating from excessively high harmonics.

Switchgear: Its power quality harmonic failures are associated with overheating, blackening, burning and blasting of Fuse and SFU units. Its Lyra/U type contact that holds both the ends of the Fuses I-type contact, overheats with harmonics current that slowly loosen its spring tension resulting abrupt Fuse/ SFU flashing or blasting. Air Circuit Breaker's (ACB) Moving Jaw (U-type contact) and Fixed Jaw (I-type contact) overheat, slowly burn and eventually blast during a minor fault or rising current within its electric power system. Molded Case Circuit Breaker's (MCCB) fixed and moving contacts welds with prolonged harmonic overheating. Power Contactor's fixed and moving contacts chatter and get welded due to prolonged harmonic overheating. Current Transformer (CT) copper winding fails- burns/ grounds/ short circuits/ or melts open. Potential Transformer (PT) winding fails- burns/ flashes/ grounds/ short circuits/ or melts open.

Bus Bars, Cable and Terminations: Harmonic issues show up as cable lug overheating, terminal insulation burning, high bus bar noise and vibrations, 3phase voltage unbalance alone the bus-bar's running length and irregular voltage drop between phases at the load ends of the bus bars or cables.

Power Transformer: Power quality failures, both with low tension (LT/LV) and high tension (HT/HV) Power and Distribution Transformers are mostly associated with transformer high voltage winding/insulation failures- burn/ ground/ phase short circuit/ or melt or open. Most failures with large sized power or distribution or equipment transformers happen due to power quality issues those cause series harmonics resonance. It happens on the interactions between the utility/grid and the plants electrical power system with presence of harmonics. Passive Tuned Harmonic Filter blocks grid/utility related harmonic resonance, improves Power Quality, mitigates harmonic distortions, and eliminates major transformer failures. Another harmonic issue that affects a transformer is the presence of high harmonics within the plant or incidence of a parallel harmonic resonance on the interactions between plant Capacitors/ Detune Filters and with its electrical power systems. It could devastate the transformer winding, either in HV or LV which could fail, burn, ground, short circuit or melt open. Passive Tune Harmonic Filter solves, both series and parallel resonance problems, either the grid ignited/ initiated series harmonic resonance or the internal plant originated parallel harmonic resonance. It suppresses both the voltage and current harmonics. It provides the most comprehensive Power Quality Harmonic Solutions. It reduces transformer winding temperature by up to 20-deg. Celsius depending upon power system Harmonic Distortions, increases energy efficiency, strengthens winding insulation, and enhances equipment life.

Cogeneration Steam Power Plant: Power quality harmonic problems are mostly associated with high winding temperature of the TG Alternator/ Generator. Another usual harmonic problem with power plants is AVR malfunctioning and/or voltage fluctuation. Those are either due to high harmonic distortions within the plant or incidence of a parallel harmonic resonance from the interaction between plant capacitor/ Detune Filter and its power system. Passive tuned harmonic filter mitigates AVR malfunctioning and generator overheating, and could reduce it by up to 10deg.Celsius that depending upon harmonic distortion in its electric power system. Harmonic problems at times percolate down to mechanical performance like Turbine Bearing overheating, noise, vibrations or damage. Turbine to Generator gear box and shaft high, could develop, high noise, vibrations or damage. Those happen mostly due to series harmonic resonance. Passive Tuned Harmonics Filter blocks the possibility of series harmonic resonance, eliminating failures and saving the turbine's critical components. Another major turbine related harmonic problem that Co Gen power plants encounters originate from in house plant harmonics or from the parallel harmonic resonance by the interaction of plant Capacitor/ detune filter with its electrical power systems. Turbine fails to deliver its full Power/MW capacity, and its Nozzle Chest Pressure rises close to its tripping limit at much lower delivery. Nozzle chest pressure tripping limit is about 80% of its inlet steam pressure value. Passive Tuned Harmonic Filters suppress both voltage and current harmonics from the TG Generator terminal and within its entire electrical power system. It thus slashes the turbine's nozzle chest pressure down up to 30% depending upon harmonics distortion. It debottlenecks Turbine capacity limitation and helps in releasing excess turbine capacity. It enhances turbine efficiency in terms of fuel/steam consumption per unit of power/kWh generated.

Furnace Loads: Power Quality harmonics cause power electronics failures- Thyristors/ SCR/ Diodes/ IGBT with for power Rectifiers and Inverters of heating furnace, automobile common hear exchanger manufacturing furnace, and Induction Furnaces (IF). Further it causes transformer failures for Electric Arc Furnace (EAF), Submerged Electricals Arc Furnaces (SEAF).

Encon Smart Solutions: It reaches right at the melting pot wherein the problems of bad Power Quality lie and mitigates it effectively and very efficiently. Encon Tuned Harmonic Filter reconstructs the distorted sinusoidal waveform back into sine wave, and mitigates the bad Power Quality and associated voltage fluctuations and sags. The extent of harmonic distortions in an Electrical Power System, or for that matter the spread of bad Power Quality, depends upon the immunity of an electrical distribution system, which is namely the short circuit impedance stability of the power system.

This simple fact delineates the Power Quality and Harmonic Distortion Correction Project is not a mass manufacturing process, but a custom designed solution. It also explains why worldwide many a peer solutions with Active Harmonic filters are increasingly translating into a medicine worst than the disease itself. An on-site power quality analysis and harmonics distortion measurement is a safer approach though not mandatory, if the power system is not fairly complex and power system data could be made available.